As Australian retail approaches the busiest time of the year, it is important for brand owners to remember there is no anticipating when a product recall might occur.

A product recall was issued on 16 December this year for contaminated baby spinach and quickly escalated over subsequent days to include more products and more states. The contaminant, a weed that can have health consequences if consumed, resulted in several people across the country falling ill.

Although most organisations are careful to avoid and prevent adverse effects, on occasion, there are risks that ultimately require management through a product recall.

Ensure preparedness

Organisations should prepare to manage product recalls as a routine process. A well-managed recall doesn’t have to result in a crisis. Having a solid recall process and system in place becomes an effective strategy for managing risk. Investing in this level of preparedness allows brand owners and manufacturers to act quickly in the event of a product safety issue – even when the world would like to be taking a break.

To ensure proper preparedness, organisations can think about risk from a likelihood perspective, for instance conducting threats and vulnerabilities assessments and mock recalls. Continually looking to take corrective, risk-mitigating actions.

Collaboration is key

While testing labs play a key role in evaluating affected products, it’s just as important that other stakeholders, such as the food allergic community, are part of any recall conversation.

All companies would do well to develop a network of experts to facilitate collaboration. Particularly for small companies, there are experts that can be consulted to assist in planning for and managing product recalls.

Industry bodies such as Food Standards Australia New Zealand (FSANZ) or health departments may also be able to offer advice. It is also helpful to leverage opportunities to learn from other recalls that have taken place and understand if a similar situation could affect your business.

Mitigate the impact of a product recall

- Understand that product recalls are rare and are high-pressure situations.

- Be as prepared as you can with a plan and a team that can swing into action as soon as an issue arises.

- Develop a severity matrix to know when you will act and what the course of action will be. You don’t want to spend lots of time thinking and planning when things go wrong.

- Act quickly. Don’t sit on the fence and observe and wait as the situation can run away from you. Recall insurers have panels of experts to help clients manage product recalls. It is a good idea to get in contact with them as soon as you have an issue for assistance in managing and communicating the recall to consumers, trading partners and regulators.

- Be overcautious – issue the recall notice quickly.

- Follow the 4 stages methodology of communication;

- Communicate what you know;

- Communicate what you don’t know (what caused the contamination, how far it has spread, etc.);

- Communicate what you are doing about it;

- Communicate what customers need to do.

- Ensure the initial communication to be correct from the get-go;

- Getting the initial communication right mitigates against flow on effects. The financial impact of a recall is normally correlated to how well the recall is managed.

- Being transparent from the start helps to manage media messaging. Simple, honest communication is important. Communication with a company’s own staff is as important as communication to external people.

- Social media means things escalate quickly. It’s important to be on the front foot. Be transparent with what you do know – provide information and fill the gap so that others don’t fill them. Always deal only in facts.

- Be aware of supply chain issues when planning for things that could go wrong. Go back through the supply chain at all touchpoints – from raw product, to warehousing, distribution, retailer, etc, and ensure you are comfortable with everything that is being done.

- Prepare a positioning statement linked to the values of your organisation.

- Check the suppliers of your suppliers as these can have a flow-on effect to manufacturers.

- Conduct mock recalls with external parties to uncover unknown shortfalls you may have.

- If a product safety incident does occur, post incident reviews are important to improve the supply chain, your processes and to mitigate against future risk. However, even with thorough investigation, the complexity of supply chains means it isn’t always possible to uncover all the issues that contribute towards a recall incident and there may not be a single specific root cause or problem with manufacturing or distribution. To mitigate these types of risk product labelling is critical. Manufacturers need to find a way to communicate risk to consumers in the absence of the ability to address issues uncovered through a clear root cause.

Recalls inspire fear in many manufacturers. They certainly aren’t something to be relished but are relatively rare. However, doing the hard work required to ensure that an organisation is prepared to successfully manage a recall in the unfortunate event that it occurs means that everyone from supplier to consumer can still enjoy Christmas.

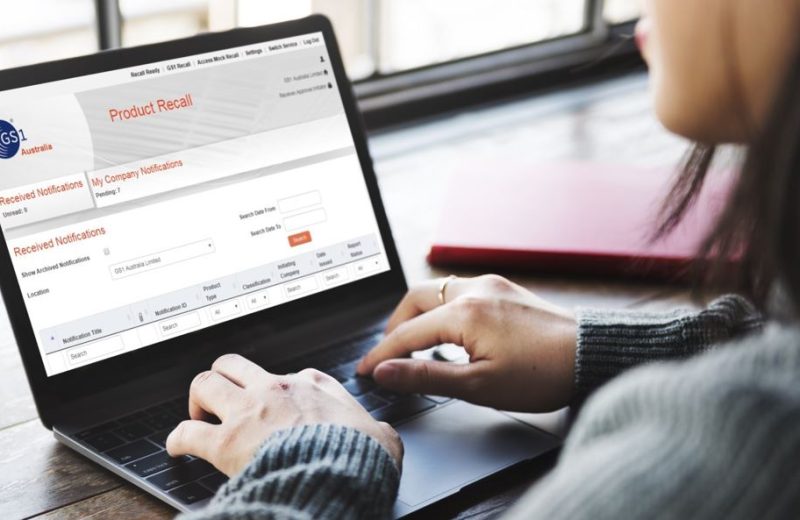

GS1 Australia Recall is used by hundreds of companies as part of their strategy for managing risk. Find out more at Recall – GS1 Australia.